CNC Router, Laser, Plasma; Custom Activation, Experiential Fabrication

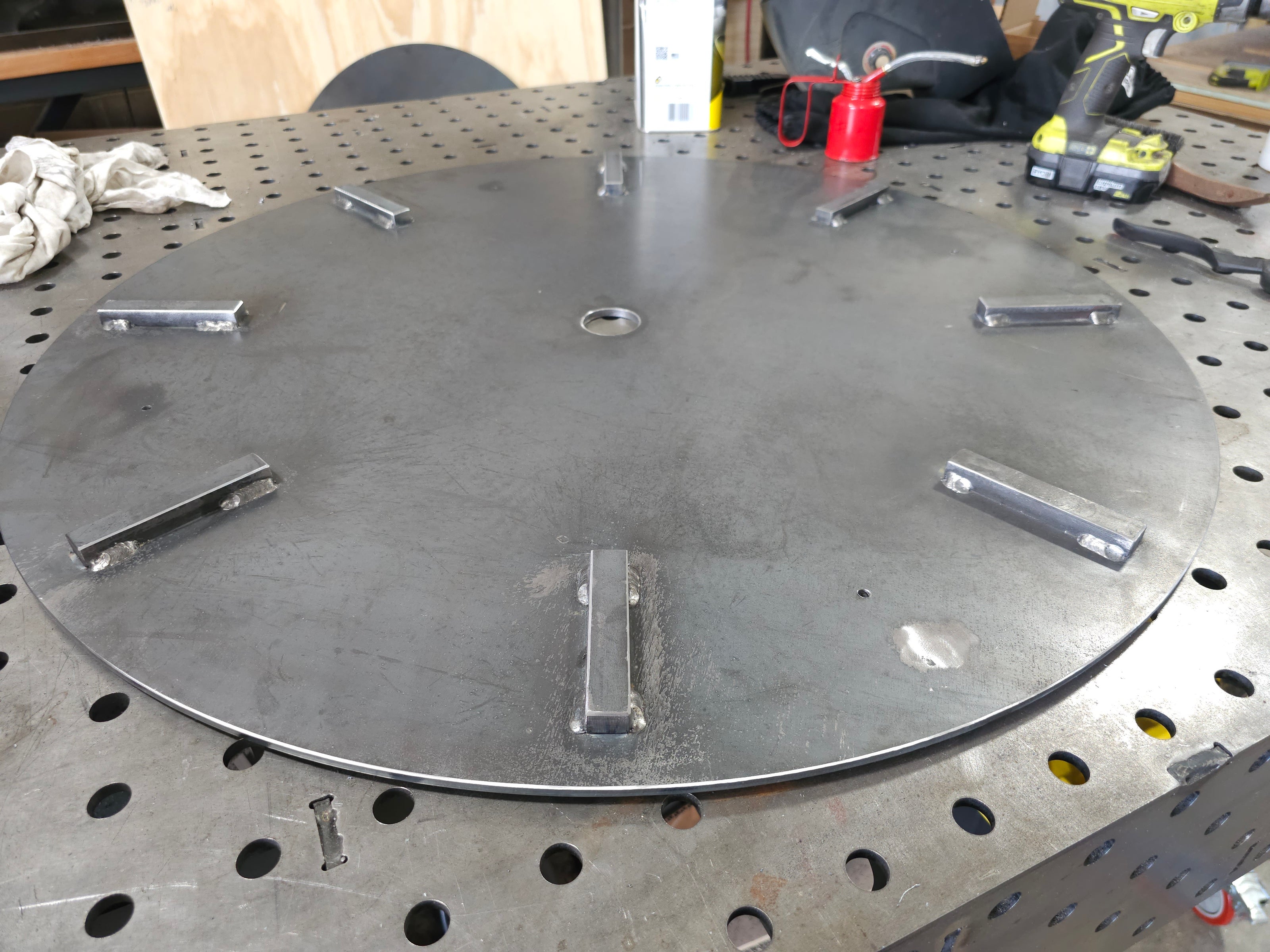

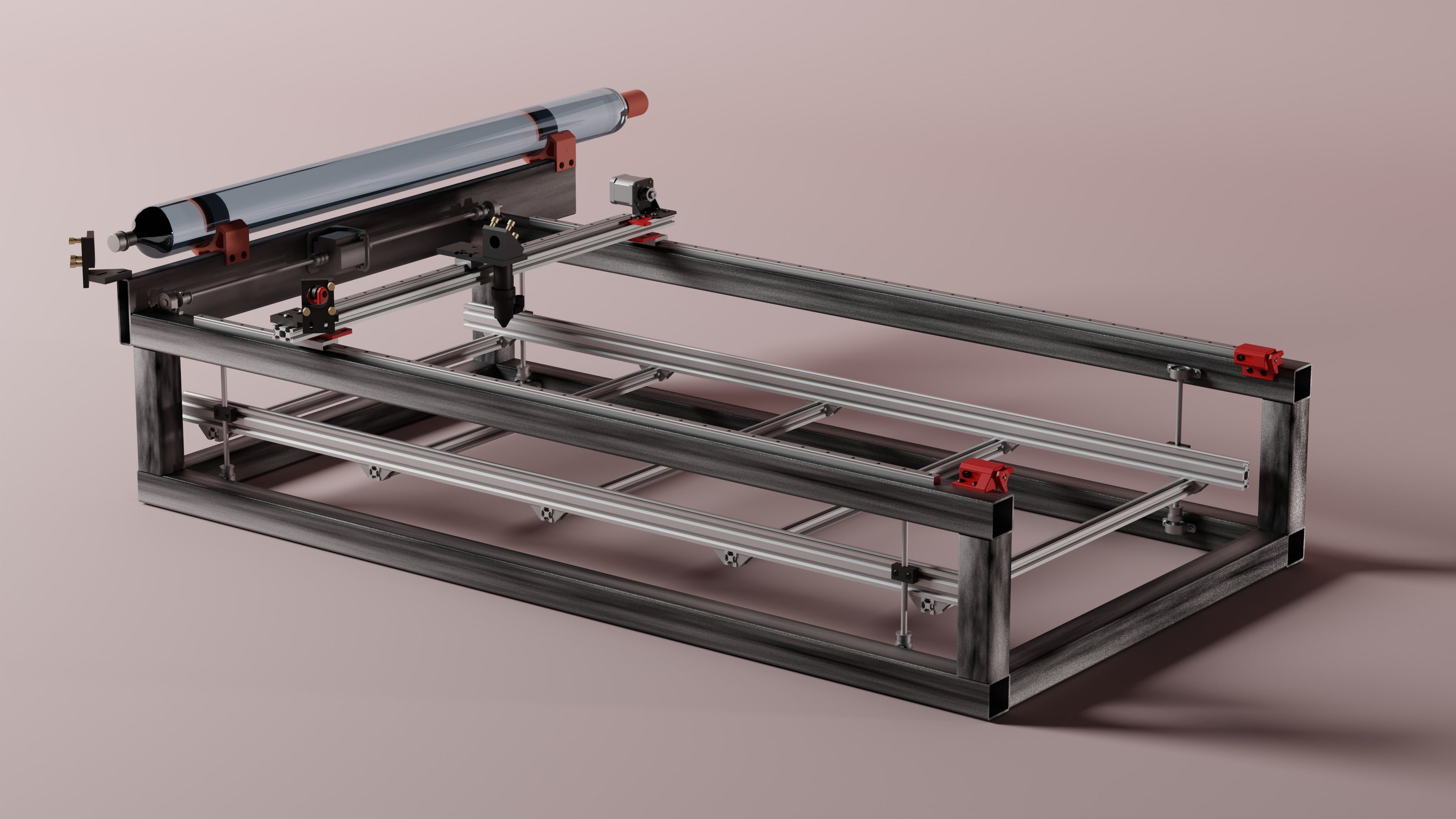

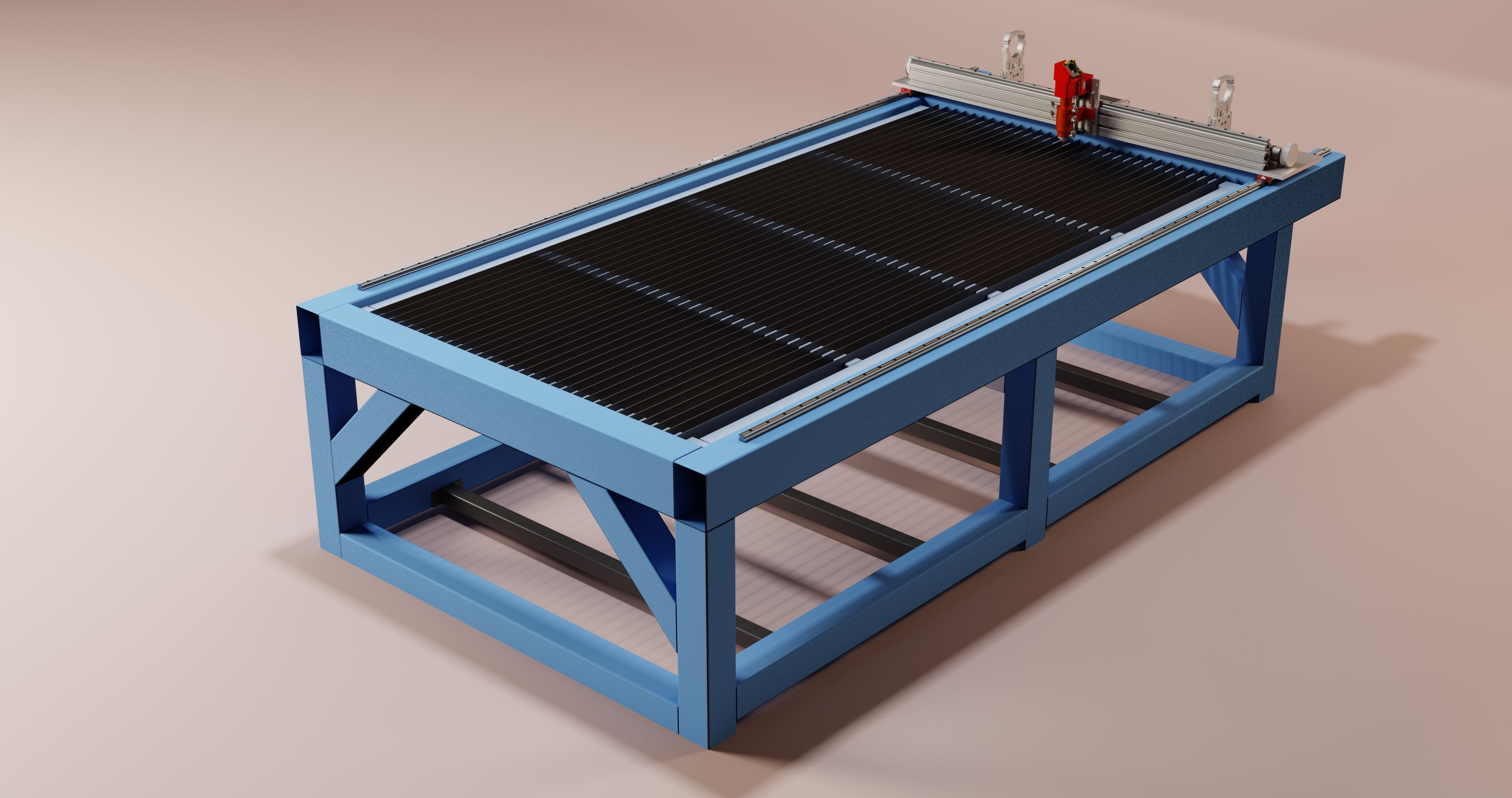

I have personally custom-built each machine used to create the products you see here.

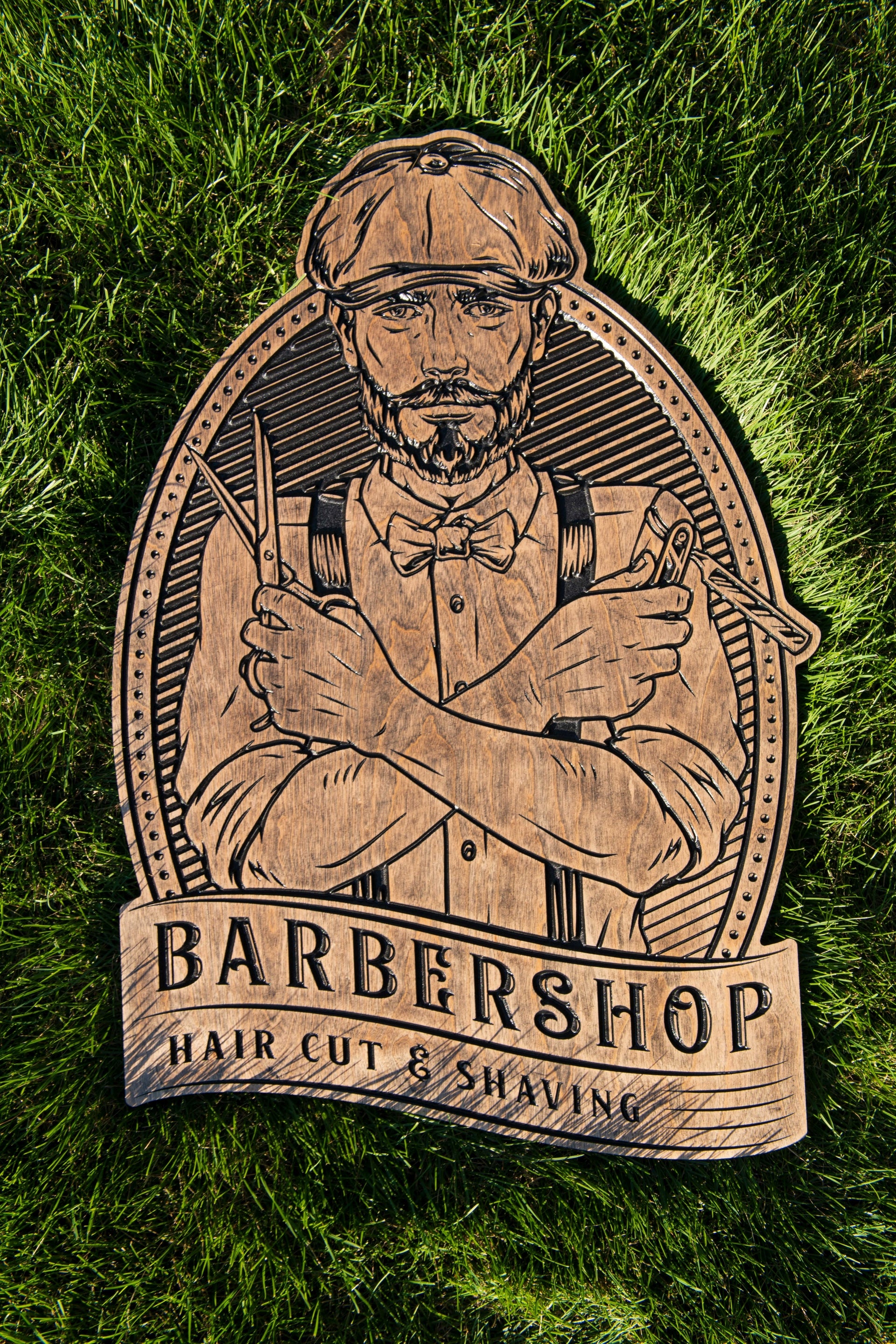

Specializing in superior quality 3D signage, custom laser cut and personalized items, large scale festival art installations, barn quilts, acrylic templates and so much more.

Items for Purchase

-

Chiara Wooden Arch Backdrops

Explore HERE -

Laser Cut Shapes & Blanks

Explore HERE -

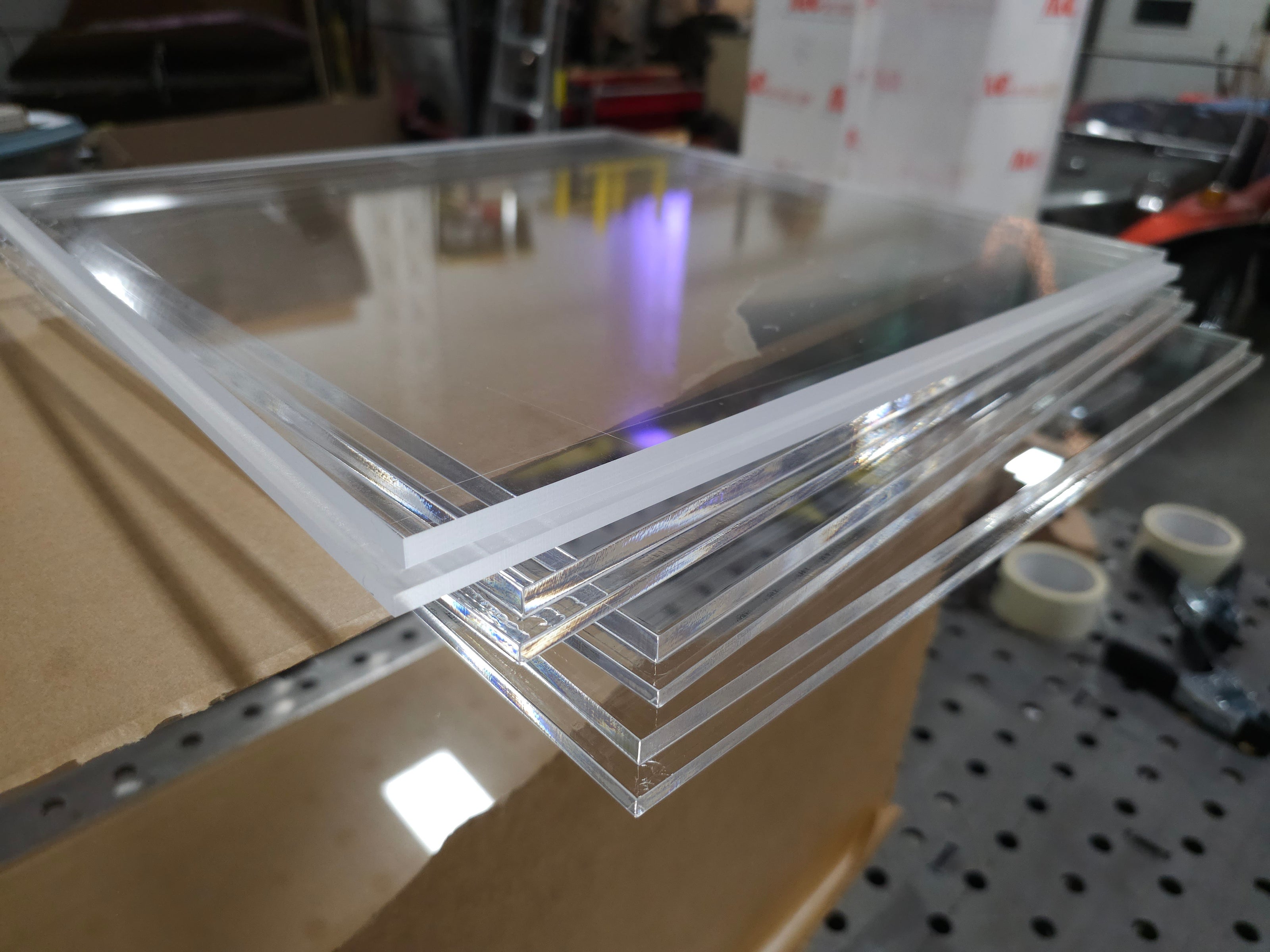

Raw Materials for Makers & Creatives

Explore HERE

Lollapalooza 2024 Custom Fab

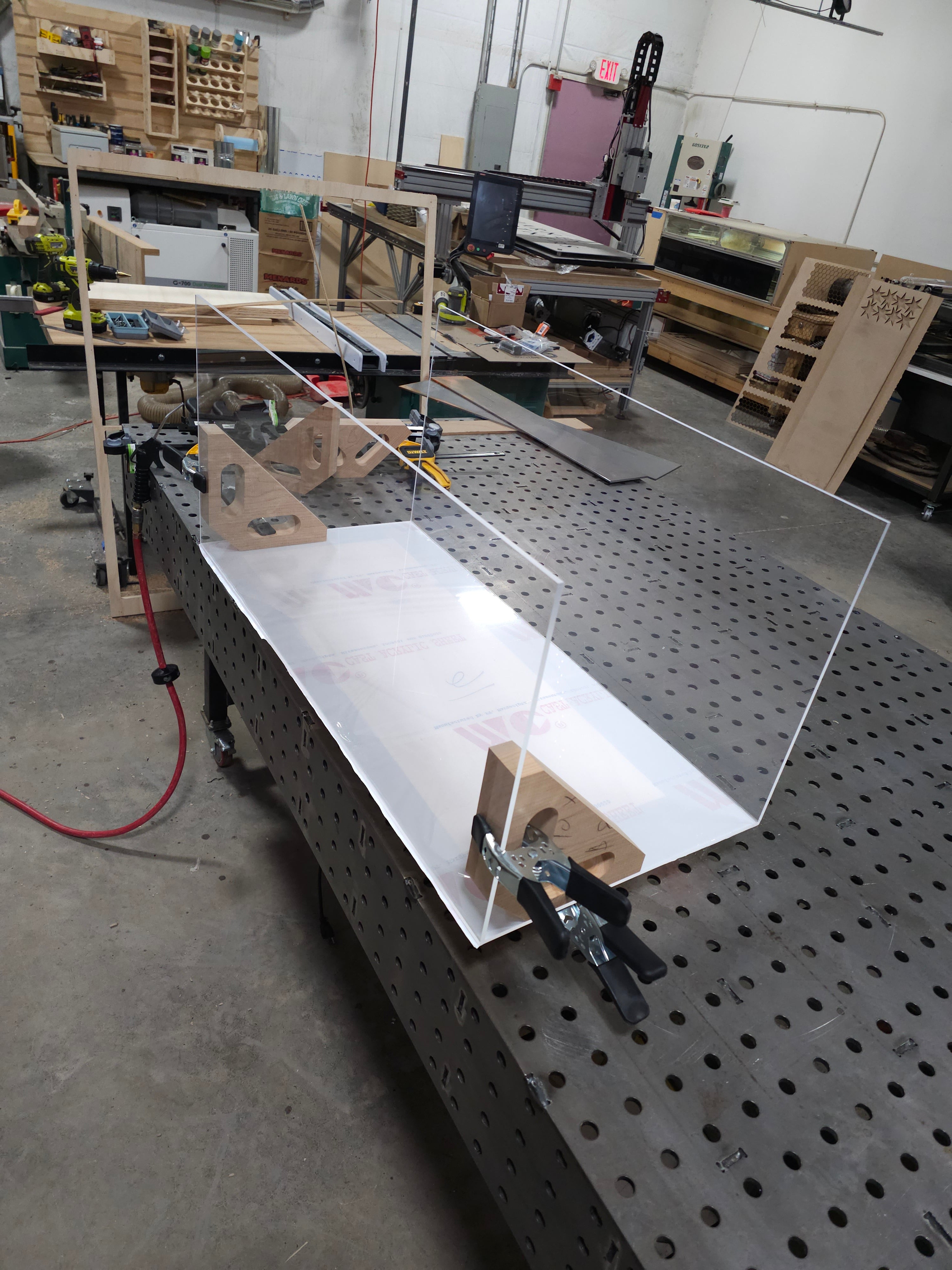

CNC milling a custom product for a customer

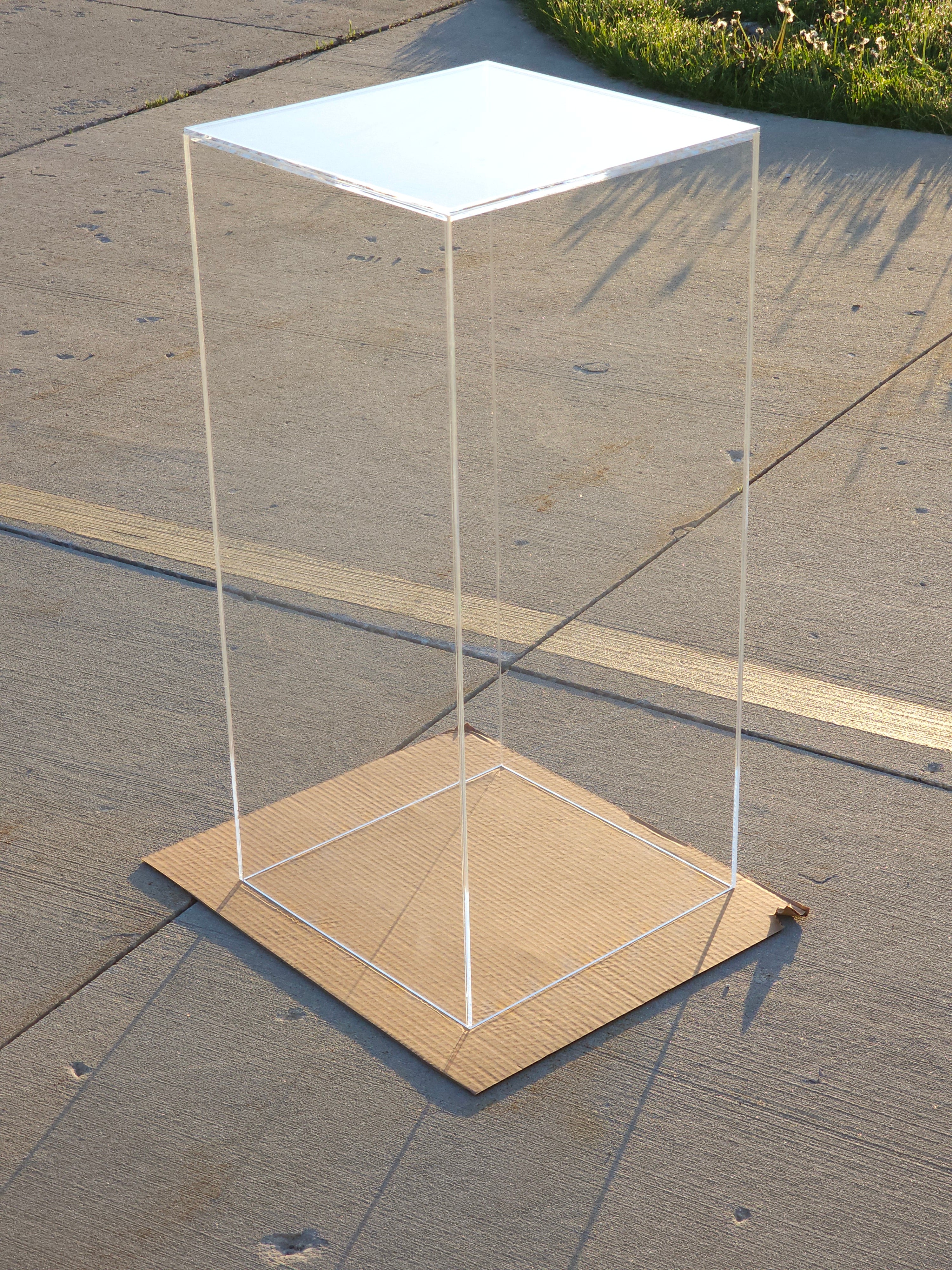

Chiara Party Backdrops

Laser Cutting

Custom Built Laser Cutters

Equipment

4x8 CNC Router (custom built)

4x8 Flatbed 100w Laser Cutter (custom built)

Two CNC Plasma Cutters (custom built)

CNC Lathe (custom built)

Two 2x4 Laser Cutters (custom built)

Bambu X1-Carbon 3D printer

Cabinet saw

8" Jointer

14" Bandsaw

Services

CNC Routing, Laser Engraving, Custom Acrylic Templates, 3D Printing, Die-cut Stickers are some of the services I can offer. Both local and nationwide.

-

Party Backdrop and Asset Fabrication Service

Regular price $425.00Regular price -

3D Printing Service

Regular price $100.00Regular price -

Custom Tumbler Engraving Service

Regular price $28.00Regular price -

Custom CO2 Laser Cutting Service (Plainfield, IL / Chicago Area)

Regular price $50.00Regular price -

Die-cut Sticker Service

Regular price $50.00Regular price -

CNC Routing Service

Regular price $350.00Regular price